The Basic Principles Of machining

After you structure a part, it’s as vital to think about wall thickness as The fantastic thing about the design.

Precision machined things are all-around in daily goods like car engines, electrical motors or maybe clocks. Nations such as Switzerland and Germany Use a status for there substantial benchmarks of precision engineering and nowadays still do a very good position of it. Other nations also have a lesser of this name including Japan and Good Britian.

Various-slicing-edge resources have more than one leading edge and frequently realize their movement relative to your workpart by rotating.

The best Side of machining

Wish to thank TFD for its existence? Explain to a pal about us, add a backlink to this page, or stop by the webmaster's web page without cost fun information.

This technique is used for the development and modification of household furniture, shoe lasts, brush handles, boats, golfing golf equipment and even more. CNC grinding, On the flip side, makes use of a disc, belt or abrasive wheel to supply automatic precision material removing and floor finish. CNC chopping features a broader number of Software options, Even though the completed merchandise is none the much less specific. A cutting equipment could make use of laser, water jet, knife, flame or plasma approaches depending on the advantages and drawbacks they provide in certain applications.

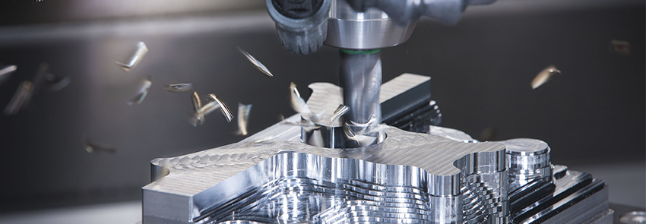

The milling method gets rid of content by accomplishing many different, modest cuts. That is achieved through the use of a cutter with lots of tooth, spinning the cutter at significant pace, or advancing the material throughout the cutter slowly but surely; most frequently it is some mixture of these three approaches.

These equipment are operated by specialized and trained machinists. The precision machining system consists of a cutting Device that removes material with the workpiece. In order for the cutting tool to try and do its occupation, it must be moved in directions specified to create the correct Slice. This primary motion is known as the “cutting pace.†The workpiece will also be moved, known as the secondary motion of “feed.†Collectively, these motions and the sharpness with the cutting Resource enable the precision device to work. Find out more:

Wire Electrical Discharge Devices (EDMs) get an entirely distinctive approach to CNC machining in that they rely on conductive resources and electricity to erode the workpiece. This method can Slash any conductive content, together with all metals.

Details, Fiction and precision machining

Nonetheless, two standards which have observed In particular wide usage would be the Morse #two official source and also the R8, whose prevalence was pushed by the popularity with the mills constructed by Bridgeport Equipment of Bridgeport, Connecticut. These mills so dominated the marketplace for these kinds of a long time that "Bridgeport" is almost synonymous with "handbook milling device". Most of the devices that Bridgeport created in between 1938 and 1965 utilised a Morse taper #two, and from about 1965 onward most applied an R8 taper. Add-ons[edit]

CNC equipment might also get the job done with a range of products from primary aluminum and plastics to far more unique materials like titanium — generating them The perfect equipment for almost any task.

What is precising definition? The term precise indicates marked by exactness and accuracy ofexpression or depth. It can also be employed to emphasize that just one isreferring to a precise or certain detail.

Your time and effort is valuable. Our on the net quoting and automatic CNC machining procedures let for rapid-change machined sections inside of times of uploading a CAD product.

The Basic Principles Of machining

It is evident that milling devices as a distinct course of device Instrument (independent from lathes operating rotary files) initial appeared concerning 1814 and 1818. The centers of earliest improvement of true milling equipment were being two federal armories with the U.S. (Springfield and Harpers Ferry) along with the varied non-public armories and within contractors that shared turnover of competent workmen with them. In between 1912 and 1916, Joseph W. Roe, a respected founding father of equipment Software historians, credited Eli Whitney (among the private arms makers mentioned higher than) with manufacturing the primary correct milling device.[18][19] By 1918, he considered it "Likely the 1st milling device at any time built—absolutely the oldest now in existence […].